HEAT TRANSFER

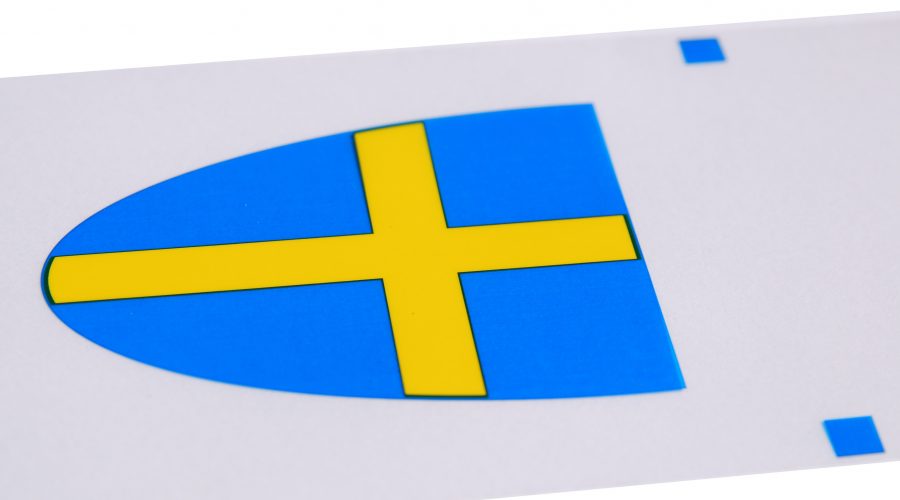

Multi-Color Heat Transfer Decals

Modern heat transfer decorations offer an attractive and economical way to decorate your product. Heat transfer decals is a cost effective way to print a multi-colour image in one decorating pass with a low environmental impact. The multi-colour design is screen printed on to a polyester carrier and transferred to the substrate in one pass by the hot stamping method. Providing a cleaner, faster and very resistant decoration. Heat transfer decoration is a dry printing method using heat, dwell time and pressure to decorate the part. To apply the heat decals a vertical or roll on hot stamping equipment is used. The polyester film has an eye-mark between the images to be registered in the machine. The decal image releases by heat and pressure from the carrier and bond permanently to the plastic part. Handling and packaging can be made immediately after decoration. You can stamp heat transfers on flat, curved, concave and convex surfaces. Heat transfer is recommended where high volume and multi-colour, tight registration is required. An extra protective lacquer for superior resistance can be supplied. No dying times, solvents, ink mixing or clean up time is required. Heat transfer is a clean, dry and environmentally friendly printing process. What is the difference between hot stamping foils and heat transfer decals? Hot stamping is a one colour application, heat transfer decals multi-coloured. Heat transfer is a proven high quality and durable alternative to ink and pad printing. Available in any design upon request, heat transfer decals give you unlimited possibilities. Our custom designed heat transfers are manufactured to meet today´s demanding industrial requirements.

Advantages

- Custom designed high performance multi-coloured prints transferred in a singled print

- Cost effective in higher volume applications

- Quick release application

- Diverse choice of gloss and matte finishes

- Excellent in colour separations and opacity

- UV exposure and resistances against ultraviolet radiation

- Heat transfer decals have superior adhesion and durability

- Excellent scratch and chemical & alcohol resistance, excellent adhesion and abrasion resistance

- Excellent coverage and easy release

- Clean dry process. No pollution, no inks or clean up time is necessary at the end of the operation

- No drying times are required. Can be handled directly after image application

Used in areas

House wares, toys, cosmetics, sporting goods, automotive, sports, electronics, personal care, rubber products, toothbrushes, industrial, medical

Heat transfers can be printed on most plastics including

Polypropylene, polyethylene, styrene, PVC, ABS, acrylic, acetate

Other material: Leather, coated wood, coated paper and cartons

Stamping temperature

90-120C vertical

110-130C roll on

Speed

2500-3000 impressions per hour

Shelf life

6 month

In additional we can provide heat transfer equipment, silicone rubber dies, fixtures, make-ready materials.